Product classification

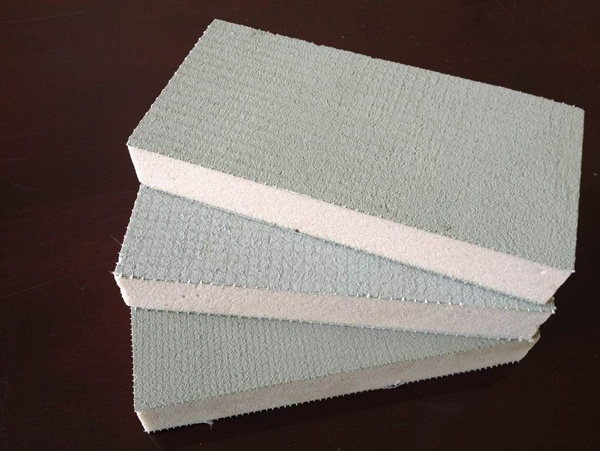

Exterior wall insulation board

Product Details

1. Overview

Our country has a vast territory, and the national standards divide the country into five thermal climate zones: extremely cold areas, cold areas, hot summer and cold winter areas, hot summer and warm winter areas, and warm areas.

Since the 1990s, with the rapid economic development, the construction industry has also developed rapidly, greatly improving the living and working conditions of the people. In recent years, the annual growth rate of completed residential areas has been over 10%. With economic development and rising living standards, air conditioning has begun to enter public buildings such as shopping malls, office buildings, hotels, restaurants, and theaters, leading to a sharp increase in non-industrial electricity consumption in cities. If this trend continues, it will inevitably affect the sustainable development of the economy, making energy-saving measures imperative.

Currently, China's building materials industry is in a period of structural adjustment, with many old processes and products being eliminated. In April 2005, the Ministry of Construction successively issued the "Notice on Strictly Implementing Energy-saving Design Standards for New Residential Buildings" and the "Energy-saving Design Standards for Public Construction," strictly enforcing the "Energy-saving Design Standards for Residential Buildings in Hot Summer and Cold Winter Areas." The energy loss in Chinese residential buildings is roughly 50% from walls; about 10% from roofs; about 25% from doors and windows; and about 15% from basements and floors. To achieve a 50% energy-saving rate by 2010, comprehensive renovation of building exterior walls is required, and the market for wall insulation materials will significantly increase. Energy-saving building materials, especially insulation materials for walls and roofs, will be favored as people become familiar with their energy-saving effects. Moreover, the new energy-saving building materials industry formed as a result also has broad market prospects.

The high-tech product developed and produced by Shandong Innovation Building Materials Complete Equipment Co., Ltd. — internal and external wall insulation board equipment is bound to have a broad market prospect and promote the rapid development of the energy-saving building materials industry.

2. Equipment Features

This machine adopts a roller pressing board-making process, completing the entire production process of the board in one go from insulation layer, fabric laying, main material application, compounding, to re-pressing. The equipment has a high degree of automation, is easy to operate, runs smoothly, and can produce various energy-saving products of different specifications and materials (the insulation core material can be foam polystyrene board, extruded polystyrene board, rock wool board, glass wool board, VIVA wood fiber cement board, FOREX beautiful rock cement board, etc.) according to customer requirements. The product surface is smooth, flat, and has high density, fundamentally changing the complicated construction process of expanded polystyrene board thin plaster exterior wall insulation projects, improving construction speed and economic benefits.

3. Project Features

1. Simple production raw materials, with no regional limitations. Mainly utilizing cement, river sand, fly ash, various insulation materials, short-cut fibers, or fiberglass cloth, processed and formed in one go by this equipment. The production process is simple, cost-effective, requires low investment, and yields quick results.

2. The equipment has a high degree of automation, is easy to operate (workers can start work after simple training), has low labor intensity, operates on an assembly line, and the production process is noise-free, pollution-free, and has no three-waste emissions.

3. The production process has low energy consumption, does not require high temperature or high pressure, and can be formed at room temperature, with no special requirements for production site conditions.

4. Can produce various insulation boards of different specifications (length, width, thickness) and materials according to different customer requirements, meeting the needs of different consumers.

4. Product Features and Performance

(1) Performance

Taking the insulation layer of 2-8cm thick XPS extruded polystyrene board or rigid polyurethane foam board as an example, the thermal conductivity of the insulation layer is <0.029w/(m2•k), water absorption <1% (v/v), compressive strength: ≥250Kpa, moisture permeability coefficient: ≤2.0Ng(m.s.pa), fire performance reaches the national B1 level standard. At the same time, different thicknesses of insulation layers can be selected according to the energy-saving design requirements of different regions, truly achieving insulation in the north and heat insulation in the south, maximizing the conservation of precious energy.

(2) Characteristics

1. Insulation and heat preservation, aesthetically pleasing decoration, efficient construction, cost-saving, unique structure, safe and reliable, lightweight and high strength, saving construction time.

2. Absorbing many advantages of modern external wall insulation from both domestic and international sources, the prefabricated panels integrate multiple functions such as insulation, heat preservation, decoration, environmental protection, weather resistance, rain resistance, frost resistance, sound insulation, earthquake resistance, and lightweight. They also have good construction and connection methods, with no cold (heat) bridges, no leakage, effectively avoiding falling and cracking phenomena, while also featuring simple construction, no seasonal restrictions, and dry construction.

3. The insulation and decoration integrated system not only meets and exceeds the specifications of JG149-2003 "Thin Plaster External Wall System with Expanded Polystyrene Board," JG158-2004 "External Wall Insulation System with Adhesive Powder Polystyrene Particles," and JGJ144-2004 "Construction Technical Regulations for External Wall Insulation," but also meets the relevant testing requirements for national standard external wall insulation energy-saving building materials.

4. Internal and external wall insulation boards can be applied to all regions, including extremely cold areas, cold areas, hot summer and cold winter areas, and hot summer and warm winter areas. They are ideal insulation and decoration materials for civil and public building walls; they can be used for external wall insulation decoration of new buildings, energy-saving renovation of existing buildings, known as "dry-hanging insulation curtain walls," and can also be used for indoor decoration, ceilings, etc.

5. Internal and external wall insulation boards — insulation and decoration integrated system, thermal conductivity ≤0.029W/(m•k), water absorption ≤1.5%, washability ≥50000 times, artificial aging resistance ≥5000h, standard state, after freeze-thaw, insulation layer pull-off strength ≥0.2 MPa, wind pressure resistance value 6.7kpa, weather resistance can withstand 80 cycles of hot rain and 5 cycles of hot and cold, the surface can remain beautiful for over 20 years, and the system's weather resistance reaches 50 years.

6. Energy-saving and environmentally friendly: The production process does not require high temperature or high pressure, the product is non-toxic, harmless, pollution-free, and non-radioactive, belonging to a new type of green energy-saving building materials.

5. Investment and Production Conditions

The wall panel production line includes: production workshop, raw material warehouse. Factory area of 300m2-800m2 or more, with 10-16 personnel, ordinary water supply, and electricity of 8-20kw.

6. Benefit Analysis

(1) Cost Accounting

(1) Raw materials: (2) Wages: (3) Water and electricity costs: (4) Equipment depreciation: (5) Management costs: Total.

(2) Profit Analysis (using medium-sized equipment as an example) Daily production of 2600m2, sold at a price of 元/m2, daily profit: 2600m2 × 元/m2 - 2600m2 × 元/m2 == 元

7. Production Acceptance Matters

1. Sign a contract printed by the Industrial and Commercial Bureau.

2. Provide national-level inspection reports and other certification materials.

3. Interior and exterior wall insulation board equipment, available in large, medium, and small sizes based on daily production capacity and degree of automation, providing a full range of services including technology, equipment, and on-site installation and debugging to ensure the production of qualified products.

Key words:

Related Products