Product classification

Cement-based homogeneous insulation board production line

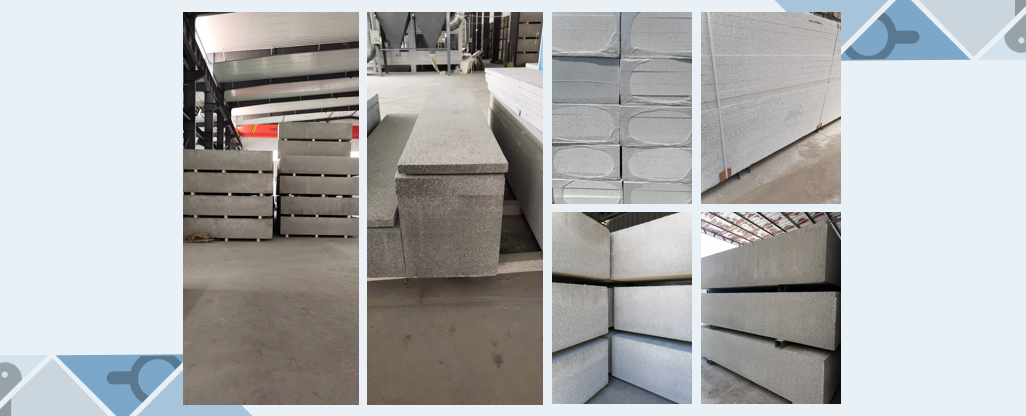

The cement-based homogeneous insulation board production line mainly consists of mixing cement with EPS particles, which are then pressed into shape using a mold. After demolding, the boards are cut and packaged for shipment. The operation is simple, and the process includes formula and equipment operation, with on-site installation and debugging.

Product Details

Cement-based homogeneous insulation board production line

1. Company Profile

Shandong Chuangxin Building Materials Complete Equipment Co., Ltd. is mainly engaged in the research, development, and promotion of decorative technology, building materials technology, and machinery. It is a modern group enterprise integrating science, industry, and trade. Its various patented products are sold across the country, with some products exported to Russia, Southeast Asia, Hong Kong, Taiwan, and other countries and regions. Years of operation have accumulated rich assets and intellectual property rights, achieving high economic and social benefits, and enjoying a high reputation in society.

In the information age full of opportunities and challenges, all employees of the company will adhere to the business philosophy of "taking the market as the criterion and technology as the guide," carry forward the company spirit of "only innovation can bring competitiveness and vitality," take on the heavy responsibility of technological breakthroughs, raise the banner of revitalizing the industry, and work together with friends from all walks of life to explore and advance on the road of high technology, develop together, and create a better tomorrow.

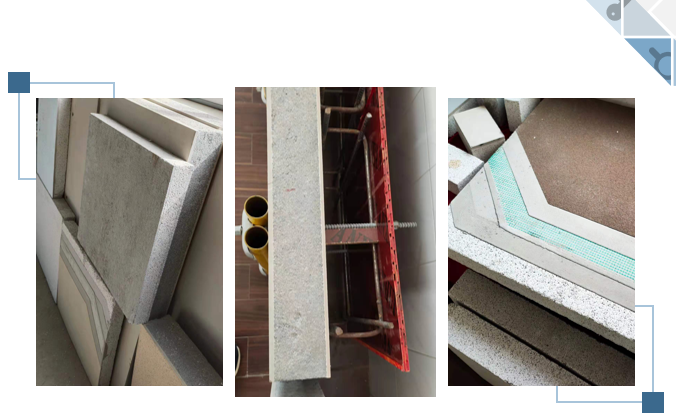

2. Molded Cement-based Homogeneous Insulation BoardCharacteristics of A-grade homogeneous board products:

(1) Durable, long service life, aging resistance, weather resistance, sun exposure resistance, freeze-thaw resistance, can last as long as the main structure.

(2) Strong plasticity, can be shaped freely, provides excellent insulation for special-shaped buildings, and can insulate difficult areas such as windows, doorways, and side walls, effectively eliminating thermal bridge phenomena and improving energy-saving effects.

(3) Good overall sealing, strong insulation and heat resistance, under the same thermal resistance conditions, the temperature amplitude on the inner surface decreases, and the time for temperature values to appear is extended, thus having better thermal insulation.

(4) Due to its strong affinity with the main structure, it has no gaps or cavities, giving this product advantages such as wind pressure resistance and earthquake resistance.

(5) Strong breathability, can eliminate wall dampness, mold, and other phenomena.

(6) It is a fireproof and flame-retardant material, an odorless and harmless environmentally friendly product.

3. Molded Cement-based Homogeneous Insulation BoardProduct Applications

The homogeneous board is lightweight, high strength, low water absorption, good weather resistance, and long service life. Its performance exceeds that of EPS foam boards and other insulation materials, making it particularly suitable for use in cold northern regions. This product can be used as external wall insulation boards, building fire isolation belts, basement ceiling insulation boards, building curtain wall composites, true stone paint composites, stone composite dry-hanging insulation construction; fire isolation belts; internal insulation and fire protection for public facilities such as cars, airplanes, and ships; thermal insulation and fire protection for high-temperature production equipment, such as steel mills, aluminum plants, and large high-heat boilers; indoor energy-saving fire protection in public places, such as various partition construction applications in public places; and sound insulation construction applications in various high-noise public places.

4. Molded Cement-based Homogeneous Insulation BoardCharacteristics of Production Equipment:

1. High degree of automation. From feeding to finished product formation, all processes are controlled by PLC, saving labor, and the entire production process only requires 3-5 people to complete. This fully automatic production line ensures product quality, high production efficiency, energy savings, and no pollution.

2. High production efficiency and stable performance. It takes only 18 minutes from raw materials to finished products. 25 cubic meters/hour, with a daily output of about 200 cubic meters (calculated based on 8 hours of work per day).

3. No pollution. The production process does not generate waste gas, waste residue, or wastewater.

4. Customizable products. Product specifications can be set according to needs, and it can also produce external wall fireproof boards, fireproof insulation boards, fire isolation belts, etc.

5. Injection molding and foaming: The slurry is injected into the mold for foaming, which takes about 3-5 minutes.

6. Initial curing: After the injection molding is completed, it is left to stand for several hours for initial curing.

7. Demolding: Demolding can be done once initial setting is complete and initial strength is achieved.

8. Cutting: After the blank has a certain strength, it can be cut, and the cutting specifications can be adjusted according to the needs.

5. Cement-based Homogeneous Insulation BoardProduction Process of Equipment:

Raw material measurement --- mold preparation --- spraying release agent --- putting the mixed material into the mold cart --- curing and maintenance --- demolding --- cutting --- maintenance --- inspection and storage --- delivery.

6. Other Support Conditions

1. We are responsible for equipment installation and debugging;

2. Technical training until qualified products are produced;

3. Provide technical materials, construction processes, and structural application diagrams.

Related Products