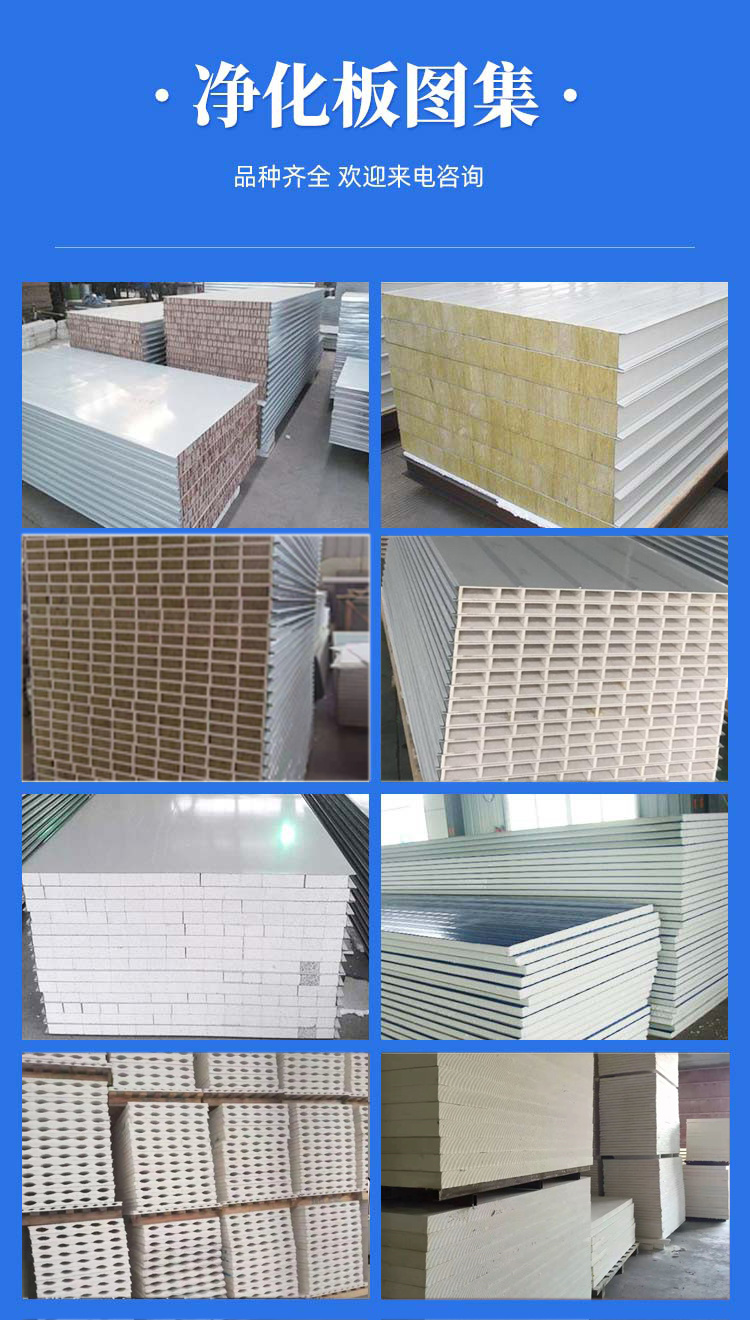

Product classification

Purification board (magnesium sulfate board) production line

Also known as clean panels, they are composite panels made from materials such as color-coated steel and stainless steel. Due to their unique effects of dust prevention, anti-static, and antibacterial properties, they are widely used in purification engineering fields that have strict indoor environment requirements, such as electronics, pharmaceuticals, food, biotechnology, aerospace, and scientific research.

Product Details

1. Company Profile

Shandong Innovation Building Materials Complete Equipment Co., Ltd. is mainly engaged in the research, development, and promotion of building materials technology and machinery. It is a modern group enterprise integrating science technology , and trade. Its various patented products are sold across the country, with some products exported to Russia, Southeast Asia, Hong Kong, Taiwan, and other countries and regions. Years of operation have accumulated rich assets and intellectual property rights, achieving high economic and social benefits, and enjoying a high reputation in society.

The company has established mechanical factories, technology development centers, decorative material factories, and craft development centers, and has close cooperative relationships with higher education institutions and research institutes in Beijing and Shandong. With its complete scientific research and production base, strong material conditions and technical strength, keen sense of trends, bold innovation, and extensive communication and cooperation with all sectors, the technology and equipment always meet the rapidly changing market needs. It is in a leading position in the industry.

In the information age full of opportunities and challenges, all employees of the company will uphold"Taking the market as the criterion, taking technology as the guide", and promote"Only innovation can bring competitiveness and vitality."The company spirit, taking on the heavy burden of technological breakthroughs, raising the banner of revitalizing the industry, and working together with friends from all walks of life to explore and advance on the road of high-tech, developing together and creating a better tomorrow.

2. Introduction to Purification Panels

Also known as clean panels, they are composite panels made of colored steel plates, stainless steel, and other materials as surface materials. Due to their unique dust-proof, anti-static, and antibacterial effects, they are widely used in electronic, pharmaceutical, food, biological, aerospace, and scientific research fields that have strict requirements for indoor environments.

Purification panels can use nine types of core materials such as rock wool, polyurethane foam, silica rock, glass wool, paper honeycomb, ceramic aluminum panels, and glass magnesium boards, as well as more than a dozen surface materials including color steel plates, galvanized plates, aluminum-zinc coated plates, stainless steel, printed steel plates, aluminum foil paper,PVC, plywood, fiber cement boards, etc., and composite panels of more than twenty types.

Description

1, purification panels are used for internal partition walls and ceilings of buildings, and are also used for the walls of mobile container houses;

2, purification panels have good self-supporting performance;

3, purification panels have good air tightness;

4, purification panels have good thermal insulation and cold bridge prevention functions;

5, the surface layer of purification panels can be color-coated steel plates, aluminum-zinc coated steel plates, and stainless steel, etc.;

6, the thickness of purification panels is50,75,100mm;

7, the width of purification panels is920-1120mm.

|

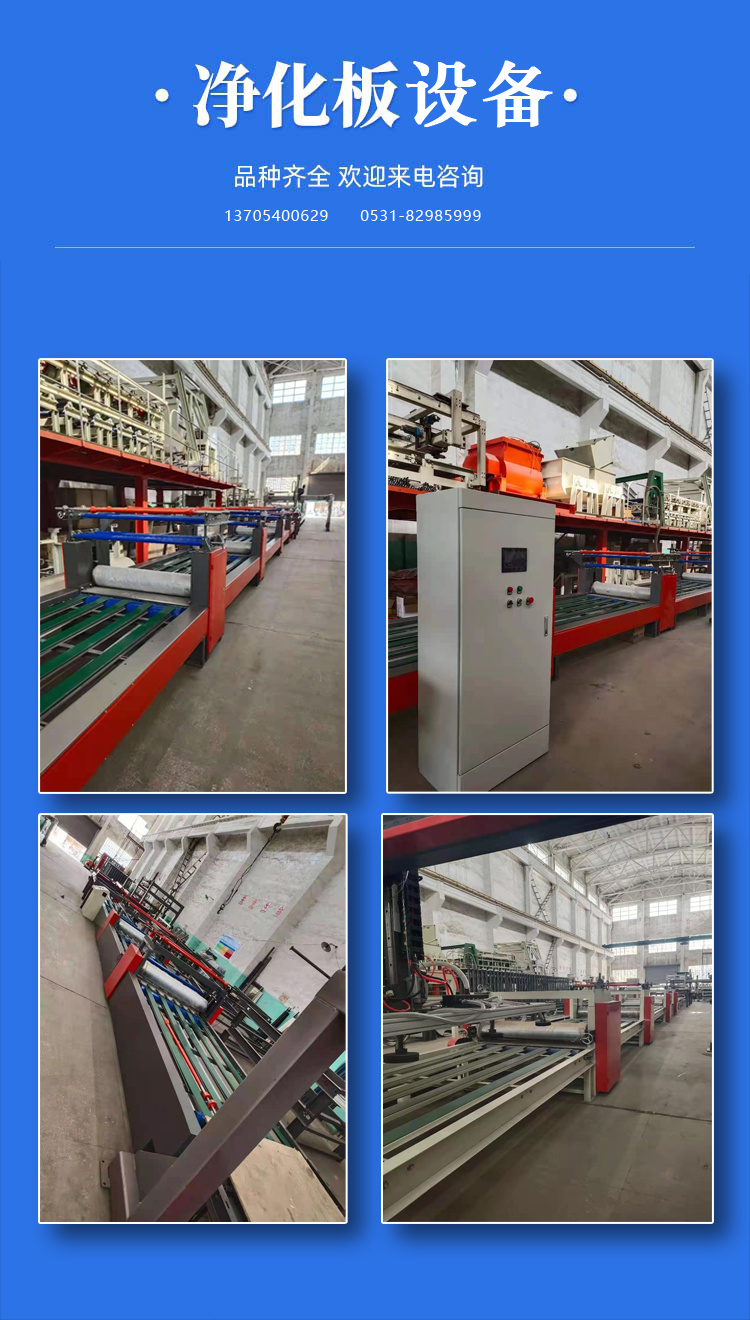

3. Purification Panel Production Equipment

The purification panel production equipment is independently developed by Shandong Innovation Building Materials Complete Equipment Co., Ltd. This production line has completely changed the situation of high labor and low efficiency in purification panel production, making it a powerful tool for purification panel production enterprises to achieve mass production, improve production efficiency and economic benefits, and realize scaled operations.

Equipment Features:

1. High degree of automation: The entire production line uses PLC computer automation control, achieving automated functions such as automatic template loading, automatic release agent spraying, automatic batching, automatic slurry application, automatic fabric laying, automatic leveling, automatic cutting, automatic re-pressing, and automatic board joining.

2. High output: The production speed of this production line is adjustable, with a batch output between 1500 to 2600 sheets, which can be adjusted according to market conditions.

3. Adjustable panel specifications: Various specifications of panels from 2-40mm can be produced, and equipment can be customized for special requirements.

4. Can produce multiple products: Various products such as glass magnesium flat panels, flue panels, composite central air conditioning ventilation duct panels, reinforced glass magnesium flat panels, vitrified microbead insulation panels, polystyrene bead insulation panels, partition panels, and external wall insulation panels.

5. Reduced labor: The entire production line uses PLC computer automation control, allowing 6 people to complete the production tasks of the entire line, with low labor intensity.

6. Precise specification adjustment: Each thickness control roller uses digital display control, with fast adjustment speed, allowing for different thickness specifications to be adjusted according to production requirements, with high adjustment accuracy.

7. Automatic cutting and separation: An intelligent cutting system is used to automatically cut various specifications of products according to specification requirements, reducing labor and improving product accuracy, ensuring fast production flow.

8. Automatic template cleaning: The production line is equipped with an automatic template cleaning system, ensuring that the back of the template is clean as new after the product is off the line. After demolding, a dedicated automatic cleaning device cleans both sides of the template again to ensure the thickness and accuracy of the panel products.

9. Automatic board unloading: Fully automatic intelligent board unloading reduces workers' labor intensity, extends the service life of templates, and reduces human damage to panels.

10. Automatic stacking and packaging: Can achieve stacking and packaging of multiple specifications and variable product quantities according to customer requirements.

11. Centralized dust collection: The entire production and subsequent sorting process is equipped with dust removal and collection devices to ensure a clean production environment, reduce pollution, improve the company's appearance, and the collected dust can be reused to lower production costs.

Installation and Debugging Cases

Installation and Debugging Cases

Installation and Debugging Cases

- Other Support Conditions

1. We are responsible for equipment installation and debugging;

2. Technical training until qualified products are produced;

3. Provide technical materials, construction processes, and structural application diagrams.

Company Address: No. 11667, Erhuan West Road, Jinan City, Shandong Province.

Related Products