Product classification

Fireproof board cutting machine technical plan (high-speed version)

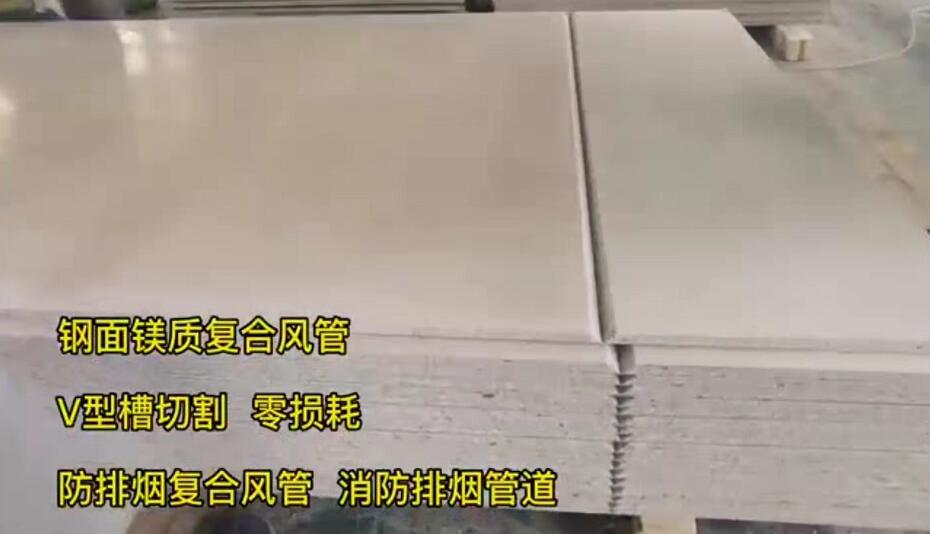

The 1340 model CNC cutting machine produced by our company is a device developed for the production of ventilation ducts, straight pipes, and special-shaped parts made from composite materials such as phenolic composite panels, magnesium crystal composite panels, and rock wool color steel composite panels used in ventilation and smoke exhaust construction.

Product Details

Shandong Innovative Fireproof Board Cutting Machine Technical Plan (High-Speed Version)

Equipment Features

The 1340 model CNC cutting machine produced by our company, is designed for phenolic composite boards used in ventilation and smoke exhaust construction,magnesium crystal composite boards, rock wool color steel composite boards and other composite materials for making straight ventilation ducts,a device for developing special-shaped parts..

It can be equipped with 1-4 electric spindles, and can install different types of tools, for different processing methods in the processing of special-shaped parts for ventilation ducts..

It can be installed with V type push knife,for opening V-shaped grooves in phenolic composite board straight pipes..

It can be installed with rollers,for folding square lines on straight composite duct pipes.,Facilitates bending..

Equipped with Shenzhen Shanlong CNC system, which has high stability,and easy operation..Office computer layout,generates cutting programs.,Copy the cutting program to the machine via USB for processing..

Standard configuration includes handwheel controller.,Allows for quick and easy tool movement.,Tool setting and other operations..

Standard configuration includes vacuum adsorption pump.,Uses vacuum adsorption to fix the workpiece..

Standard configuration includes double pressure roller feeding device.,For boards with poor vacuum adsorption effect.,Further fixation..

Equipped with Shenzhen Yankong 1.5kw servo motor.,The empty stroke speed can reach 60-80 meters/minute..Fast speed.,Stable performance.. Z-axis standard configuration includes brake system.,Prevents the machine head from falling after shutdown..

Standard configuration includes automatic lubrication system for rails.,Ensures the guide rail.,and slider lifespan..

Comes with professional ventilation duct selection software (providing hundreds of shapes for duct special-shaped parts),cutting program generation software..In addition,, fordifferent materials in the production of straight composite duct pipes with different processes.,Our company has exclusively developed a software for generating cutting programs for straight pipes.Only need to input the straight pipe dimensions, and select the processing technology to automatically generate the processing program.,Eliminates the need for drawing lines., Creating tool paths.,Generating programs and other tedious steps.,生成程序 等繁琐步骤.

Related Products